Multi-layers cell factory

Features

uSP Vl-compliant medical grade transparentpolystyrene (PS) material. The heat treatment processcombined with injection molding is adopted to make theproduct have good toughness and is not easy to bedamaged in the process of transportation and transfer.

Multi-layers cell biofactory adopts independentresearch and development of surface modificationprocess,the hydrophilicity is strong, and the cell adhesionperformance is better.

With Class C cleaning shop, and production process thatapply with lSO13485 quality management system, as well asprofessional automatic production line, all the products alsohave to pass 3 times tightness test before delivery, so as toensure 100% qualified products.

with perfect quality management system, each batch ofproducts has been tested to ensure the consistency andstability of product performance between different batches.

Double mouth design, improve the speed of filling liquidand harvesting liquid, and is not easy to produce bubbles,more conducive to gas exchange, conducive to high-densitycell culture.

Equipped with quick-cut seal cap (patented product), itcan switch between airtight and breathable state inconventional environment(greenhouse) to meet the needs ofdissolved oxygen and exhaust in different culture stages ofcells and viruses.

Double mouth design, improve the speed of filling liquidand harvesting liquid, and is not easy to produce bubbles,more conducive to gas exchange, conducive to high-densitycell culture.

Equipped with quick-cut seal cap (patented product), itcan switch between airtight and breathable state inconventional environment(greenhouse) to meet the needs ofdissolved oxygen and exhaust in different culture stages ofcells and viruses.

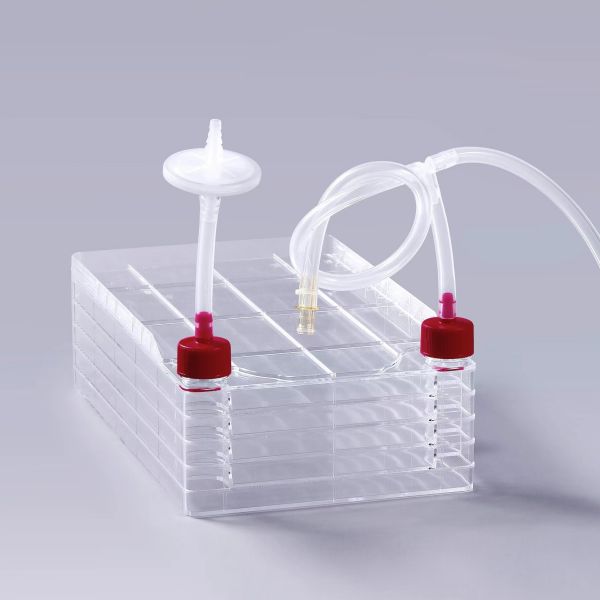

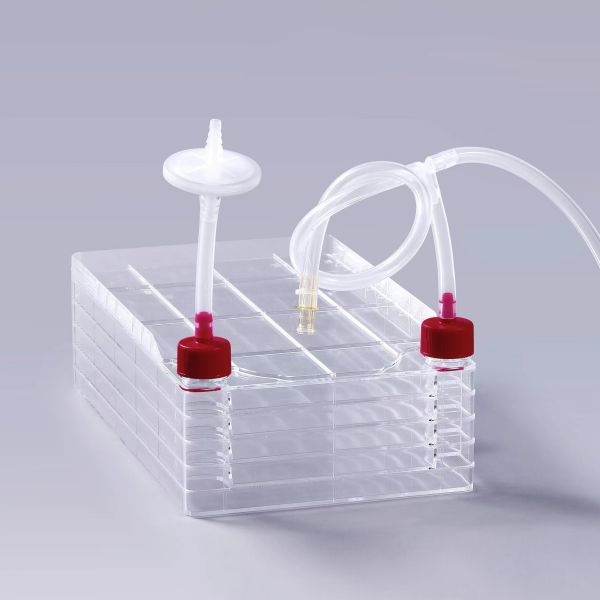

Equipped with a full set of sealed piping system, can beconnected with the liquid intake system and harvestingsystem piping, through the peristaltic pump or pressuresystem for liquid input and output.

The finished products have passed the tests of ISO10993-10, USP87 and The United States Pharmacopoeia bythird-party testing institutions (SGS), without sensitization,hemolysis, heat source and cytotoxicity.

Equipped with a full set of sealed piping system, can beconnected with the liquid intake system and harvestingsystem piping, through the peristaltic pump or pressuresystem for liquid input and output.

How do you concatenate multiple cell factories

In the large-scale culture of cells, it is common to concatenate multiple cell factories together to create a culture avoidance environment for ease of operation. This eliminates the need for multiple opening operations and reduces the risk of contamination. So, how do we tandem multiple plants?

A cell factory is a multi-layered culture container. Scaling up culture can be achieved by increasing the number of layers. However, as the number of layers increases, we run into a problem -- repeated opening of the lid. With the increase of opening times, not only the operation time will be prolonged, but also the risk of cell contamination will be increased. At this point, the developed culture components can be combined into a closed system by concatenating multiple containers. The procedure is as follows:

1. Prepare customized liquid transfer caps, media, cell factories, and connecting pipes.

2. Connect the liquid transfer cap to the medium bottle, and the cell factory to the connecting pipe in A class A environment.

3. Connect the liquid transfer cap to the connecting pipe through the quick connector to form a closed system.

4. Carry out the liquid transfer operation.After the liquid transfer, the connecting pipe can be retained on the cell factory for culture and for the next liquid exchange and passage operation.

The above is the specific operation steps of connecting multiple cell factories. During operation, we must pay attention to aseptic operation to avoid introducing external pollution and affecting the growth of cells.

Cell factory accessories introduction and features

Cell factory is a kind of multi-layer cell culture consumables, often used in large-scale cell culture or industrial cell culture, in the culture of cells, often with the help of various accessories to carry out different experimental operations. Today's rich road cell Xiaobian with you to talk about.The accessories of cell factory are generally divided into: breathable cap, seal cap, transfer cap, silicone tube, hose clamp, tee kit, connector, etc. The specific functions are as follows:

Sealed cover: The cover has no air holes. It is mainly used in conditions without carbon dioxide, such as incubators and greenhouses. A sealed cover can prevent the invasion of external bacteria and help create a good growth environment for cell growth.

Breathable cap: The cap has air holes on it. It is mainly used in the presence of carbon dioxide. Pores allow carbon dioxide from the environment to enter the cell factory and create the right conditions for the cell to grow.

Hose: including general hose and welding hose, welding hose can be hot welded. Mainly used for liquid transfer use.

Hose clamp: its function is to clamp the hose to control the flow rate of liquid, or to achieve the effect of throttling.

Joint: Connects two different hoses, common Y and T type two specifications.

Small hole conversion head: ADAPTS to small mouth cell factory or medium hole conversion cover, and connects hose for pipeline operation.

Conversion cover: generally includes a mid-hole conversion cover and a small hole conversion cover, connected to the hose for use.

Air filter: improve the air condition, control the liquid inlet speed.

The cell plant is equipped with a complete sealed piping system, which can be connected to the liquid intake and receipt systems for liquid input and output via peristaltic pumps or pressure systems.

TC treated seal cap & vent cap cell Bio-factory

| Category | Article number | Layer | Cap | TC/Non-TC | Package specification | Carton dimension |

| Cell culture factory | LRC011001 | 1 |

Vent cap

|

TC-Treated sterilization | 1pcs/pack,8pack/case | 61 X 41 X 57 |

| LRC011002 | 2 | 1pcs/pack,8pack/case | 61 X 41 X 57 | |||

| LRC011005 | 5 | 1pcs/pack,6pack/case | 56 X 41 X 57 | |||

| LRC011010 | 10 | 1pcs/pack,4pack/case | 56 X 41 X 57 | |||

| LRC011040 | 40 | 1pcs/pack,2pack/case | 78 X 57 X 41 | |||

| LRC013001 | 1 | Vent cap

|

Non-TC-Treated

sterilization |

1pcs/pack,8pack/case | 61 X 41 X 57 | |

| LRC013002 | 2 | 1pcs/pack,8pack/case | 61 X 41 X 57 | |||

| LRC013005 | 5 | 1pcs/pack,6pack/case | 56 X 41 X 57 | |||

| LRC013010 | 10 | 1pcs/pack,4pack/case | 56 X 41 X 57 | |||

| LRC013040 | 40 | 1pcs/pack,2pack/case | 78 X 57 X 41 | |||

| LRC010001 | 1 | Seal cap

|

TC-Treated sterilization | 1pcs/pack,8pack/case | 61 X 41 X 57 | |

| LRC010002 | 2 | 1pcs/pack,8pack/case | 61 X 41 X 57 | |||

| LRC010005 | 5 | 1pcs/pack,6pack/case | 56 X 41 X 57 | |||

| LRC010010 | 10 | 1pcs/pack,4pack/case | 56 X 41 X 57 | |||

| LRC010040 | 40 | 1pcs/pack,2pack/case | 78 X 57 X 41 | |||

| LRC020001 | 1 | Seal cap

|

Non-TC-Treated

sterilization |

1pcs/pack,8pack/case | 61 X 41 X 57 | |

| LRC020002 | 2 | 1pcs/pack,8pack/case | 61 X 41 X 57 | |||

| LRC020005 | 5 | 1pcs/pack,6pack/case | 56 X 41 X 57 | |||

| LRC020010 | 10 | 1pcs/pack,4pack/case | 56 X 41 X 57 | |||

| LRC020040 | 40 | 1pcs/pack,2pack/case | 78 X 57 X 41 |